Recently, the research team led by Professor Trusov of the Faculty of Materials Science at Shenzhen MSU-BIT University published an innovative study in the Royal Society of Chemistry’s journal Materials Horizons (Q1; Impact Factor: 10.7). The paper, titled “Thermogravimetry in a Gradient Magnetic Field as an Efficient Quasi In Situ Method for Studying Magnetic Phase Formation: Optimizing ε-Fe2O3 Synthesis” (Mater. Horiz., 2025, DOI: 10.1039/d5mh01134e), lists SMBU as the first affiliation.

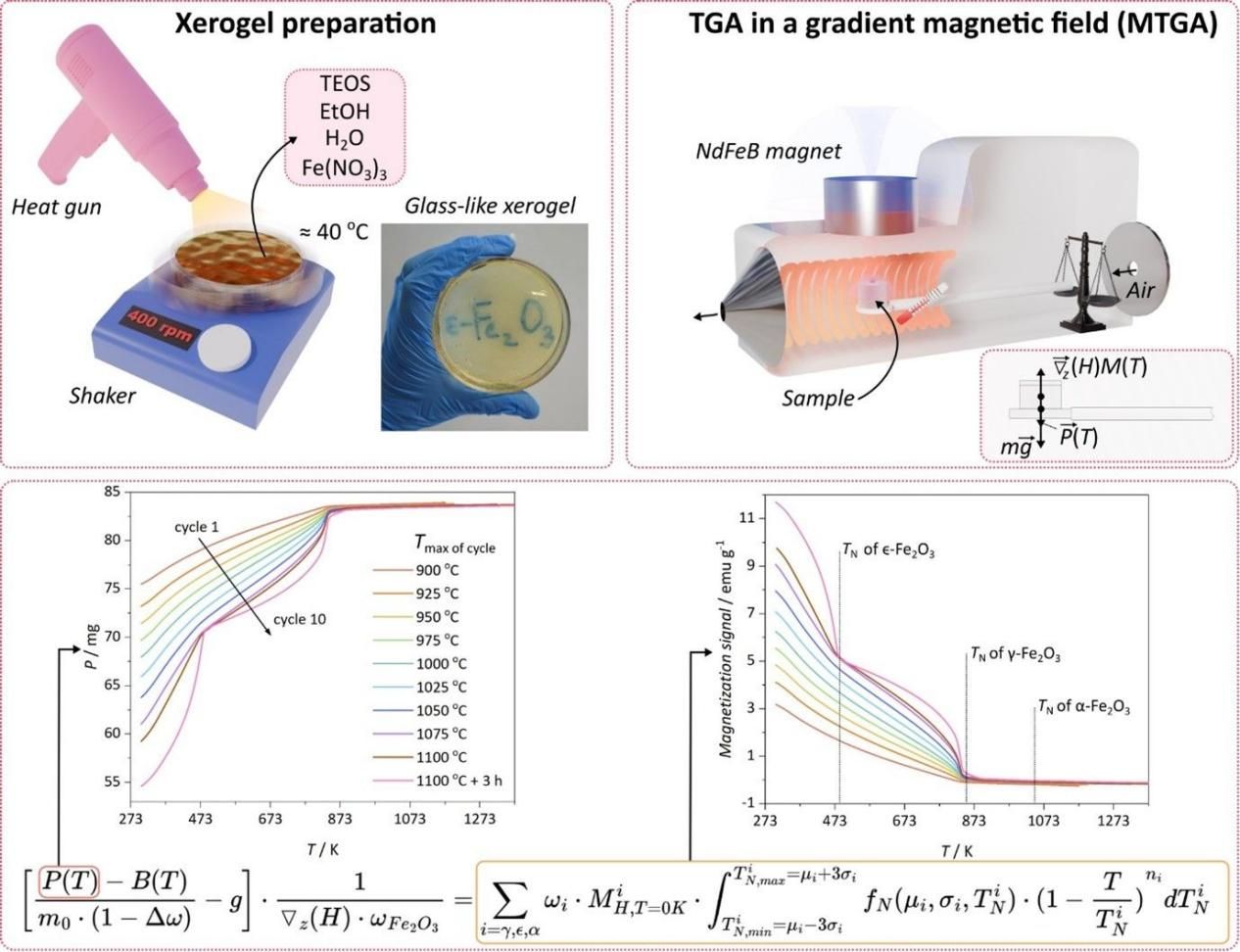

Figure: The synthesis process of Fe–Si–O precursors; schematic diagram of a thermogravimetric analyzer equipped with a magnet; experimental cooling curves (weight–temperature); recalculated cooling curves (magnetization–temperature); and the mathematical formulas used to derive phase mass fractions from these curves.

In this pioneering work, Professor Trusov’s team proposed for the first time a methodology for semi-quantitative analysis of magnetic phase composition using thermogravimetry in a gradient magnetic field. The core tool is the conventional thermogravimetric analyzer, widely used in research to precisely track sample weight changes at temperatures up to 1100°C. This instrument is simple to operate, cost-effective to maintain, and produces easily interpretable data—making it an indispensable tool in materials research. The team’s innovation lies in equipping the thermogravimetric analyzer with a permanent magnet, effectively transforming it into a magnetometer. This modification enables the instrument to capture magnetization data, thus empowering a routine laboratory device to tackle complex questions in magnetic materials research.

Professor Trusov’s research addresses a longstanding challenge in chemistry and materials science—the optimization of synthesis conditions for magnetic materials. Traditionally, solving this problem has required either time-consuming procedures or expensive and difficult-to-access in situ techniques, such as synchrotron radiation X-ray diffraction. To validate the effectiveness of the new method, the research team selected the Fe–Si–O system as the study object. From a fundamental science perspective, this system can form multiple polymorphs of iron(III) oxides—ε-Fe₂O₃, γ-Fe₂O₃, and α-Fe₂O₃—that can transform into one another under varying conditions, making it of significant research value. From an industrial standpoint, ε-Fe₂O₃ possesses highly desirable magnetic and electrical properties, but scalable synthesis methods have long been lacking, creating urgent demand for optimized approaches.

The core concept of the study involves placing the initial precursor into a thermogravimetric analyzer for thermal treatment and material synthesis (the first stage of the cycle). Immediately afterward, during the cooling process, the material’s weight is measured in a magnetic field (the second stage). The team repeated this cycle multiple times, adjusting the maximum annealing temperature and holding time in each run. This process generated a series of cooling curves correlating heat-treatment conditions with the total iron oxide concentration in the Fe–Si–O system, providing a robust dataset for subsequent analysis.

To accurately extract the mass fractions of different iron oxide polymorphs from the cooling curves, Professor Trusov’s team developed a model that accounts for the applied magnetic field and describes the analytical signal of the thermogravimetric analyzer. The breakthrough lies in recognizing that each magnetic phase has a unique “fingerprint”—its transition temperature from disordered to ordered magnetic states. This transition is accompanied by a stepwise change in the sample’s apparent weight. By analyzing the magnitude of these steps, the researchers could calculate the proportions of magnetic phases present in the sample.

Through systematic investigation, the team successfully established the relationships between the mass fractions of iron oxide polymorphs and the annealing temperature, annealing time, and total iron oxide content. Remarkably, the entire study required only 580 hours to prepare and analyze 97 samples. By contrast, using conventional methods—annealing samples in a furnace followed by laboratory X-ray diffraction analysis—would have required three times longer. This demonstrates that the method developed by Professor Trusov’s team is highly efficient. The findings promise to significantly simplify the work of researchers and mark a major breakthrough in the search for optimal synthesis conditions for magnetic materials.

From left to right: Yifan Wang (second-year master’s student, Faculty of Materials Science), Jingtong Duan (third-year PhD student, Faculty of Materials Science), Senior Lecturer Evgeny Gorbachev (Faculty of Materials Science), Senior Lecturer Roy Nygard (Faculty of Materials Science), and Professor Lev Trusov (Faculty of Materials Science), pictured beside the thermogravimetric analyzer used in the research.